Low Fire Bodies - Plainsman

Low temperature firing (cone 06-02) actually has many advantages:

- The energy, time, and effort to fire the kiln is only a fraction of what it is for stoneware.

- The edges of over and under-glaze brushwork do not bleed into the glaze.

- Bright red body colors can be achieved and the red color maintains with a transparent glaze cover (above cone 03 the glaze can turn the body color brown).

- Ware is very stable in the kiln and warping is only a problem on extreme forms.

- Results are repeatable, consistent. There is usually room for error on firing without a significant impact on the results.

- Ware can often withstand thermal shock quite well.

- The bright colors available at lower temperatures are fabulous. Commercial bottled underglaze glazes work really well and are very convenient to use.

There are some disadvantages for common low fire bodies:

- Traditional terra cotta ware lacks strength and hardness (and is therefore porous) compared to stoneware (notwithstanding this, low temperature red clays can be fluxed to have the strength of stoneware).

- Glaze is not nearly as firmly bonded to the body as it is at higher temperatures (again, this is not true if the body contains a flux that matures it at low fire).

- Glazes are more expensive.

As already noted, it is possible to create low fire bodies that fire quite vitreous and strong, infact as strong as stoneware. This can be done using special clays that have unusually low melting points or by adding melters (e.g. frits) to the body recipe.

Working and Drying Characteristics

Low fire bodies are typically quite plastic (feldspar and other fluxes are not needed in the recipe, leaving more room for clay components). Talc bodies are an outstanding example of very plastic workability coupled with excellent drying behavior (in fact their working properties are probably unrivaled by any other type of ceramic body).

Firing

For the strongest ware consider glaze firing your clay to cone 03. Or bisque fire to cone 03 and glaze to 04. To get the best defect-free surface it is important to use a custom firing schedule. It is OK to heat the ware rapidly to 100F below the top firing temperate (e.g. at 400F/hr), but then proceed at 100F/hr to the final temperature. Then hold for enough time to even out the heat in the kiln (for light ware this may only be 10 minutes), then drop rapidly 100F and hold there (e.g. for 30 minutes). Optionally you can drop more slowly down to 1500F. For cone 03 in our kiln, for example, we finish at 1950, hold 10 minutes, drop to 1850, hold 30 minutes and switch off. By doing this schedule clear glazes will be more transparent and defect free.

Glazing

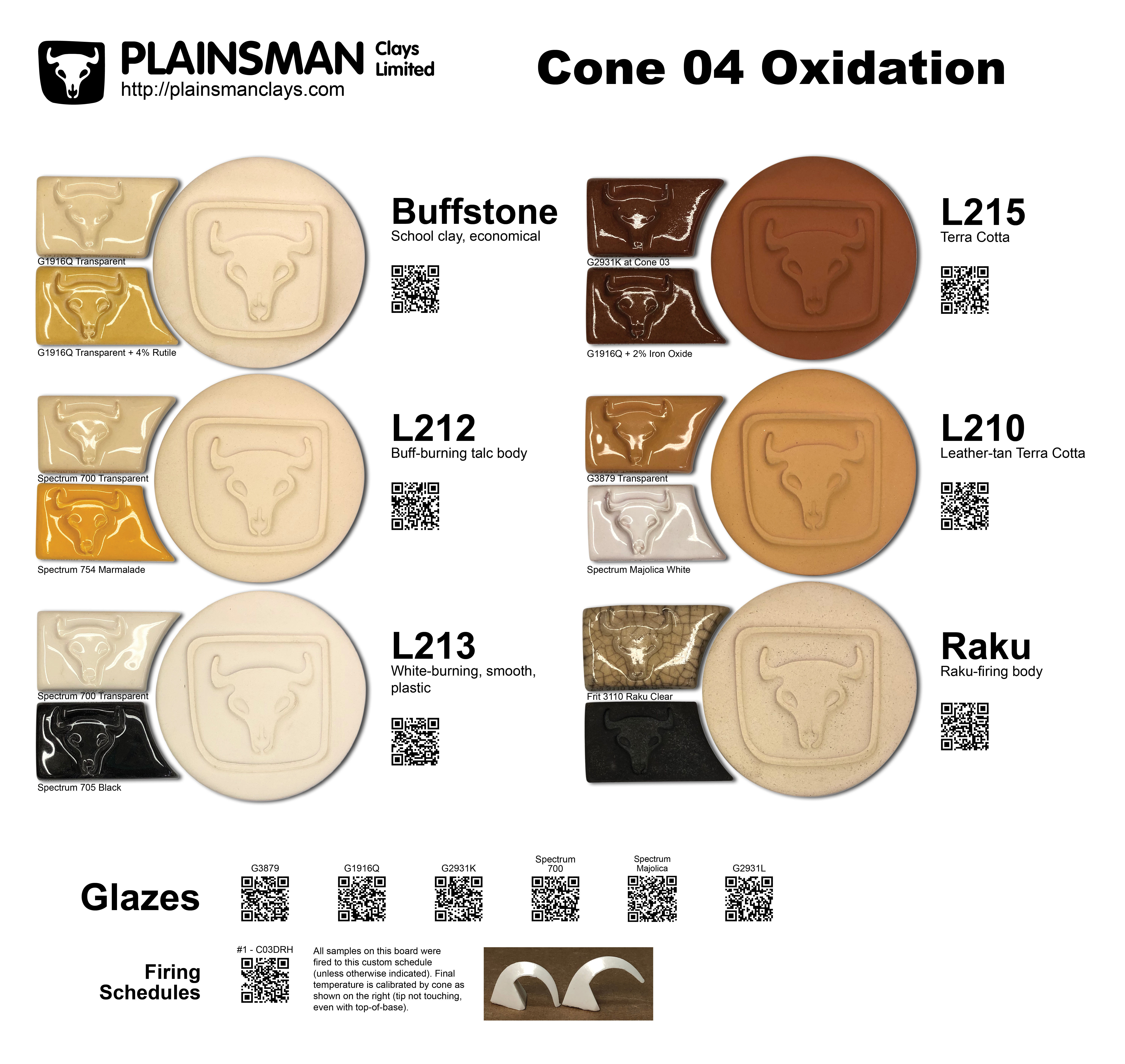

It is unusual for potters and hobbyists to mix their own low temperature glazes. Developing glazes that work well is much more difficult that for stoneware. However, if you can develop a good transparent base recipe (or use the ones we provide) and it fits the body you use, then you can add opacifiers and colorants. Thankfully, possibilities are endless using commercial glaze products. Every imaginable effect is available. Most come in small jars and are meant to be painted on (admittedly this is not practical for many types of ware). Dipping glazes are also available so that you can completely immerse ware to get an even coating, but of course, the size of ware you can glaze in this manner will be dependent on how much glaze you can afford to buy. Even the dipping glazes, however, dry quite slowly and can be difficult to use.

At low fire it is important that glazes fit (so that glaze and clay expand and contract together as the ware is heated and cooled). Glazes that do not fit will severely weaken the ware. Crazed earthenware provides a breeding ground for bacteria. Shivering glazes shed fine sharp flakes of glaze into food or drink.