Home

Glazes, Engobes

G2926B Cone 6 Clear Glossy Base Glaze

Description

For Plainsman Cone 6 Bodies. We document procedures to mix this as a brushing glaze, dipping glaze or base coat dipping glaze.

It has the lower thermal expansion necessary to fit (without crazing). It sources boron from a frit instead of troublesome Gerstley Borate.

G2926B Whiteware transparent with various stain additions on a porcelain body, M370 (bright colors do not work on dark burning bodies unless you underlay them with an engobe). This does not work well for chrome-tin stains (e.g. 6006). Mason 6020 is a body stain, it does not work in glazes (as you can see here).

Firing

It is standard practice to fire cone 6 using a hold (or soak) at top temperature schedule (e.g. for 30 minutes) to produce a defect-free glaze. However we recommend a drop-and-hold firing schedule (like PLC6DS). Both require manual programming of your kiln (because none of the built-in programs do any kind of hold). If you have not manually programmed your kiln, this is a barrier is worth crossing to produce more defect-free glaze surfaces. For the best possible surface consider a slow cool (like C6DHSC).

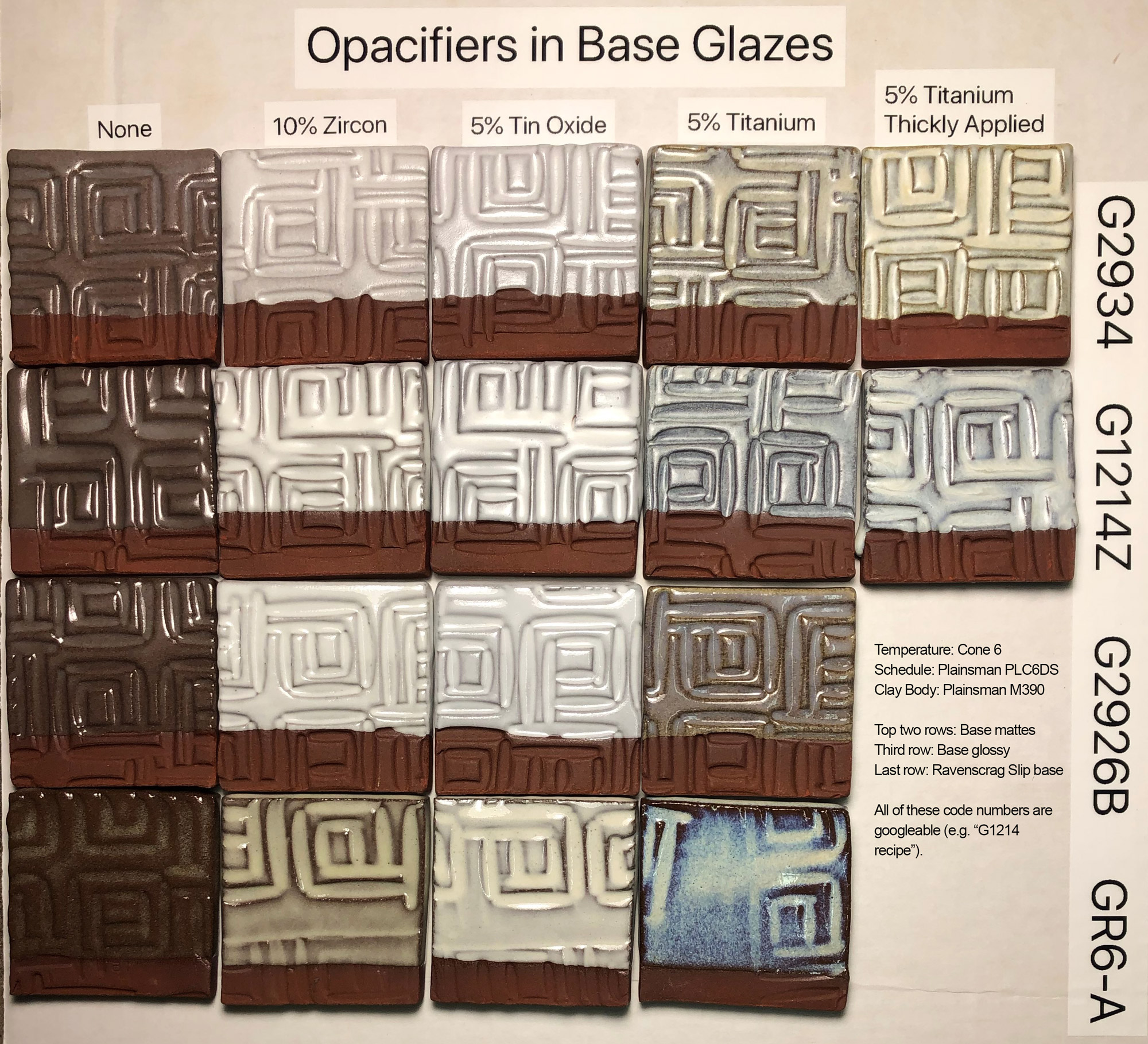

The body is Plainsman M390. These are commonly used base glazes. The top one is an MgO matte, the next is a calcium matte. They behave very differently to these additions. Notice also that thickly applied titanium dioxide is very different. Tin oxide fires whiter than zircon (e.g. Zircopax). Also, zircon opacified glazes tend to crawl so special precautions may be needed.

Glazing

When mixed with water to create a thixotropic slurry, this will perform was as a dipping glaze. It will apply evenly to bisque, produce minimal dripping and dry within seconds. It will be adequately durable for handling. If bisque walls are thin, it will be necessary to glaze the inside and outside of pieces as separate operations (with a drying time between).

If you are glaze layering (using this as a dipping glaze and painting a commercial gummed brushing glaze over it) there is a risk of crawling. It may be necessary to add some gum to this, converting it from a dipping glaze to a base-coat dipping glaze.

Recipe

The recipe of this glaze is open-source. We developed it and sell it premixed but you can batch it (or even adjust it) yourself. For detailed technical information its page at the Digitalfire Reference Library by clicking the following: G2926B.

Adding the Stains and Opacifiers: Simply multiply the weight of the amount of powder you want to use and divide by 100. For example, if you have 2000 grams of glaze powder and want to add 6% stain: 2000*6/100=120 grams of stain. Or, 10% zircopax: 2000*10/100=200 grams of zircopax (stain %'s are suggestions, for some colors you may need more, testing is needed). Bright colors and whites will be muted on dark-burning bodies.

Recipe adjustments: Starting with data code #6930 run (of Aug 2021) we began to use Fusion Frit F-12 instead of Ferro Frit 3134 (they are equivalent products). Starting with the #7034 run of Sept 2022 we began using 325 mesh silica (this gave better transparency and reduced thermal expansion for better glaze fit).

Crazing? If this crazes, perhaps on P300, we do have an alternative recipe, G2926S, that lowers thermal expansion. It utilizes a low expansion frit (either Ferro 3249 or Fusion F-69). If you are mixing your own be sure to use 325 mesh silica, that alone will likely solve the problem. Another option is to make a blend of G2926B and G2934 matte. The latter has a much lower thermal expansion and can be added in significant percentages without loss of gloss. To start try an 80:20 G2926B:G2934 mix.

Mixing Instructions

If you just want to mix it the traditional way, start with about 85 water to 100 powder (by weight) and mix well using a propeller mixer. Add more water until it is creamy, try it, adjust, etc. To learn more visit the G2926B page at the Digitalfire Reference Library.

If you want better application properties (as a one-coat dipping glaze) we recommend targeting a specific gravity of 1.44 and gelling the slurry to make it thixotropic. Water weight: Same as powder weight. Yield is about 1.4 litres per kg of dry powder.

To prepare for use as a single layer dipping glaze, add the powder to 95% of the water and mix well. Then add water as needed to get the right specific gravity. To break up agglomerates sieve through 80 mesh or blender mix the slurry. The best dipping results come with a ~1.44 specific gravity thixotropic slurry that gels and holds itself in place after dipping (this "rheological state" can change on storage so be ready to adjust it later).

This can also be mixed as a brushing glaze or a base-coat dipping glaze.

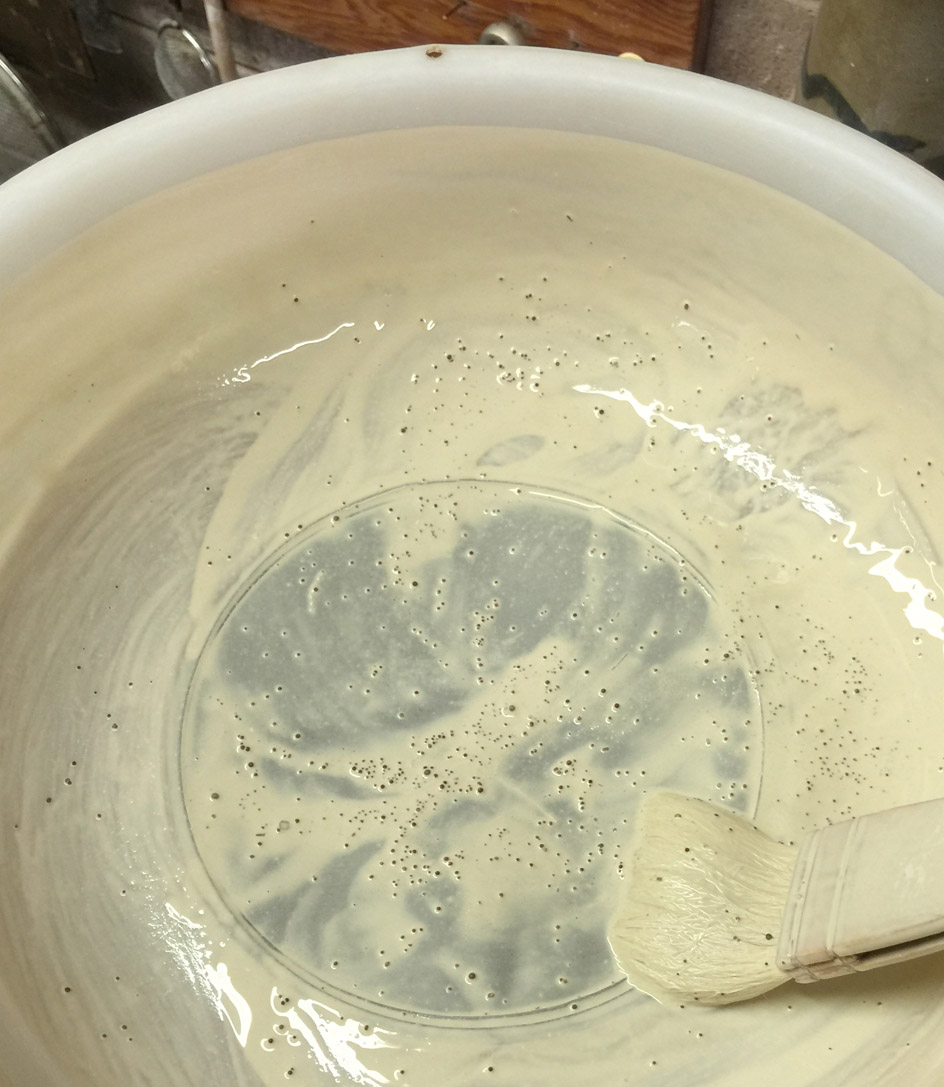

G2926B glaze can precipitate crystals like this. These can appear over time, depending on factors like temperature, electrolytes in your water or solubility in the materials (frit can be slightly soluble). The glaze slurry should be screened periodically (or immediately if you note the particles when glazing a piece). This is an 80 mesh sieve.

Gallery

Underglazes with M370 and G2926B transparent. The colors were airbrushed and the clear glaze was sprayed over top.

L3954B white engobe on M340 and M390. The engobe has been applied to the inside and wrapped over the rim to midway down the outside. The clear liner glaze is G2926B Whiteware transparent. The outside glaze on the right is that same clear with 4% added iron oxide. The outside glaze on the left mug is GA6-A Alberta Slip clear using Ferro Frit 3195 as the flux.

These Coffee clay mugs have been white L3954B engobed at leather hard stage on the insides (the center one partway down the outside). After bisque the left and right ones were white-glazed on the inside (using G2926B+10 Zircopax). The one on the right has GA6-A (Frit 3195 version) on the outside (the center mug inside and out). The GA6-A over the black clay produces a very deep, rich ultra-gloss surface. The mug on the left has Ravenscrag floating blue (GR6-E) on the outside (producing a very right color over the Coffee clay).